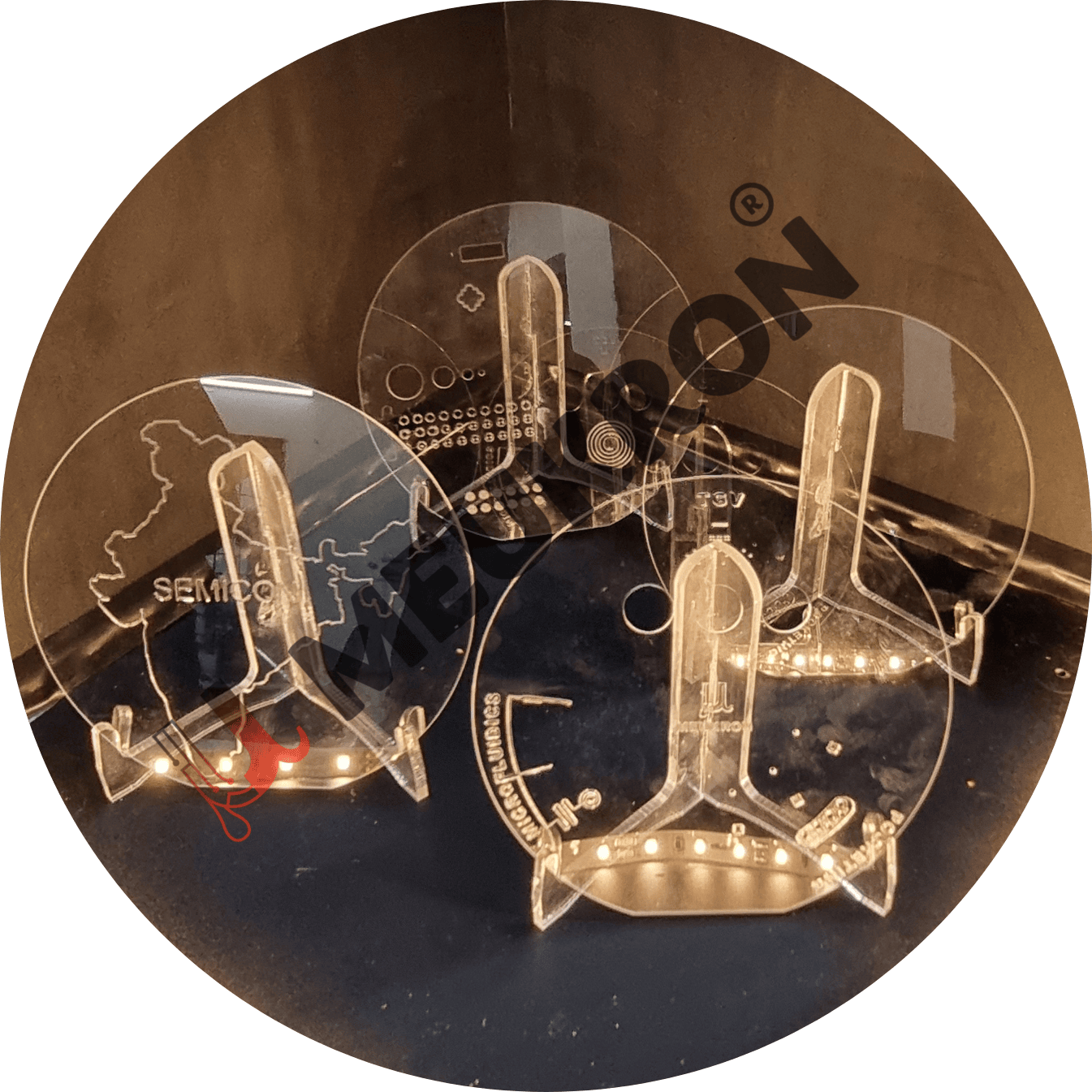

Our in-house Glass micro-fabrication tool can produce Through Glass Via (TGV), Interposers, and High-Density Interconnects. The Tool is versatile, and convenient to use.

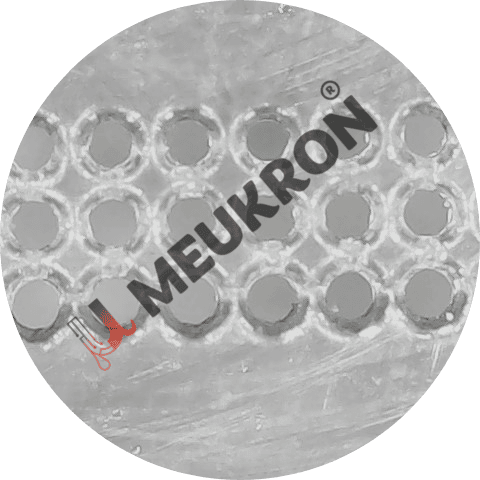

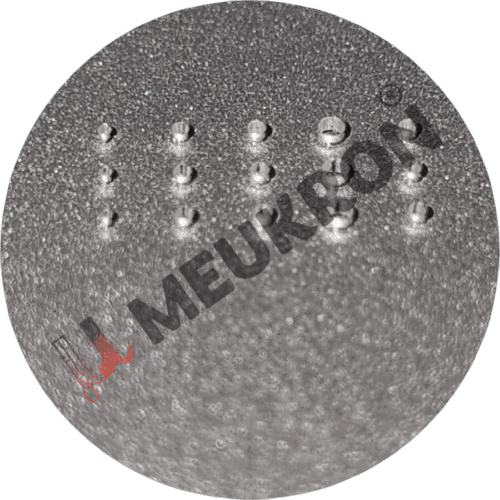

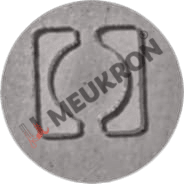

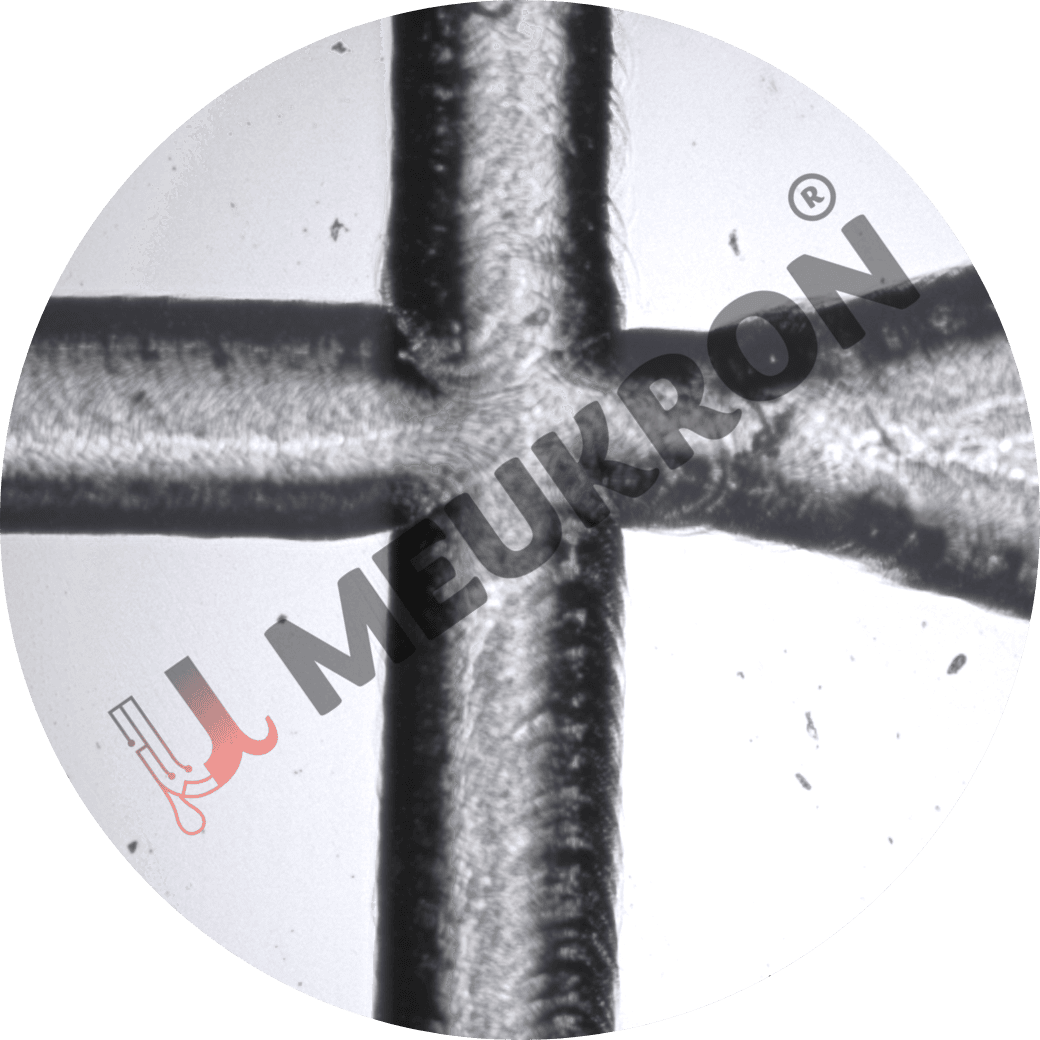

A Through‑Glass Via (TGV) is a vertical electrical interconnect that passes entirely (or partially) through a glass substrate or interposer. In effect, it’s a hole or micro‑via in a glass wafer that is then metallised (filled or coated) to allow current or signals to pass from one side to the other. Glass interposers (substrates) using TGVs are increasingly used in advanced packaging (2.5D/3D ICs, RF, MEMS) because glass offers a number of desirable physical and electrical properties.Our Capability:

1. Minimum Via Diameter - 100μm ; On special request we can do 50μm as well

2. Pitch - 2x Via Diameter

3. Aspect Ratio - 1:10

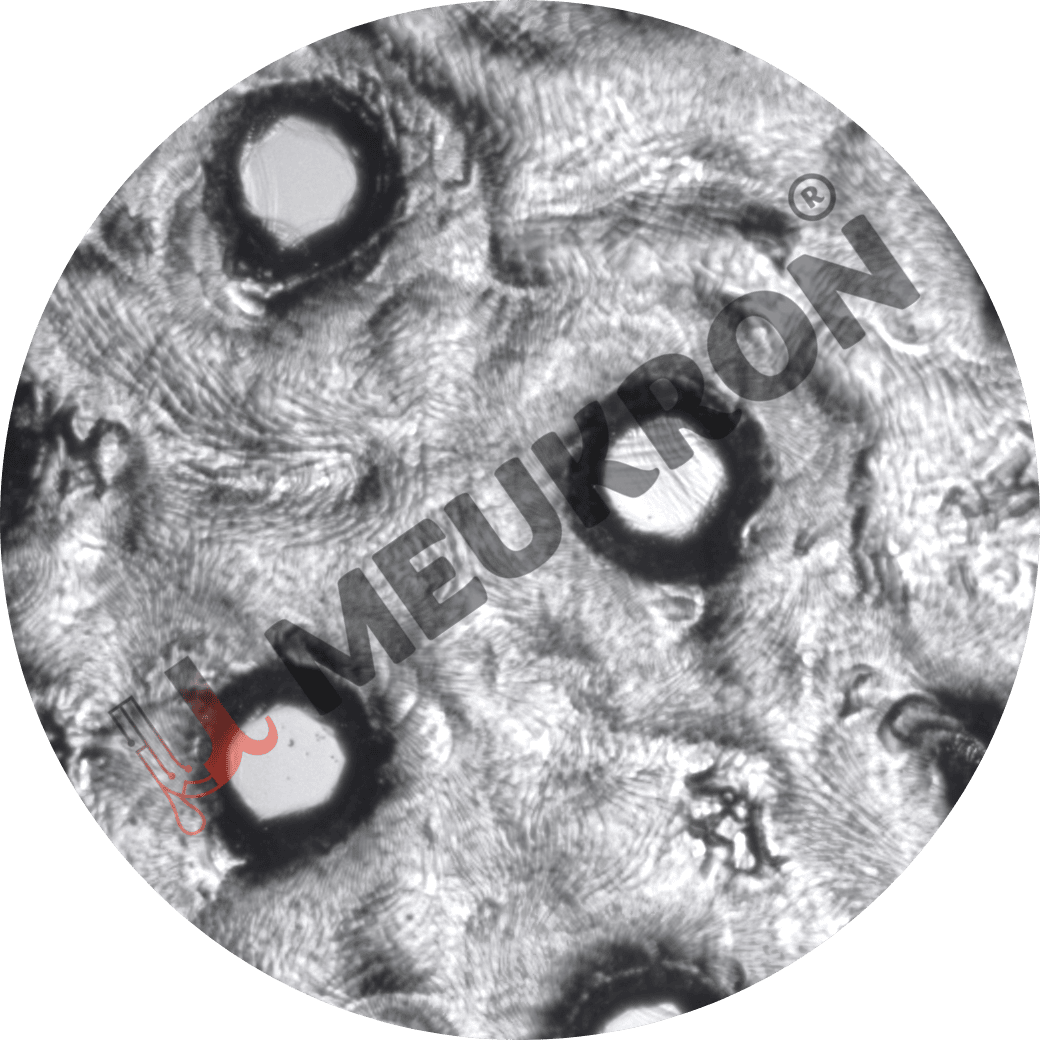

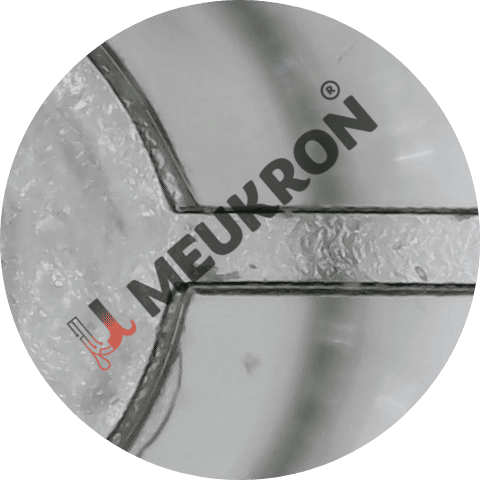

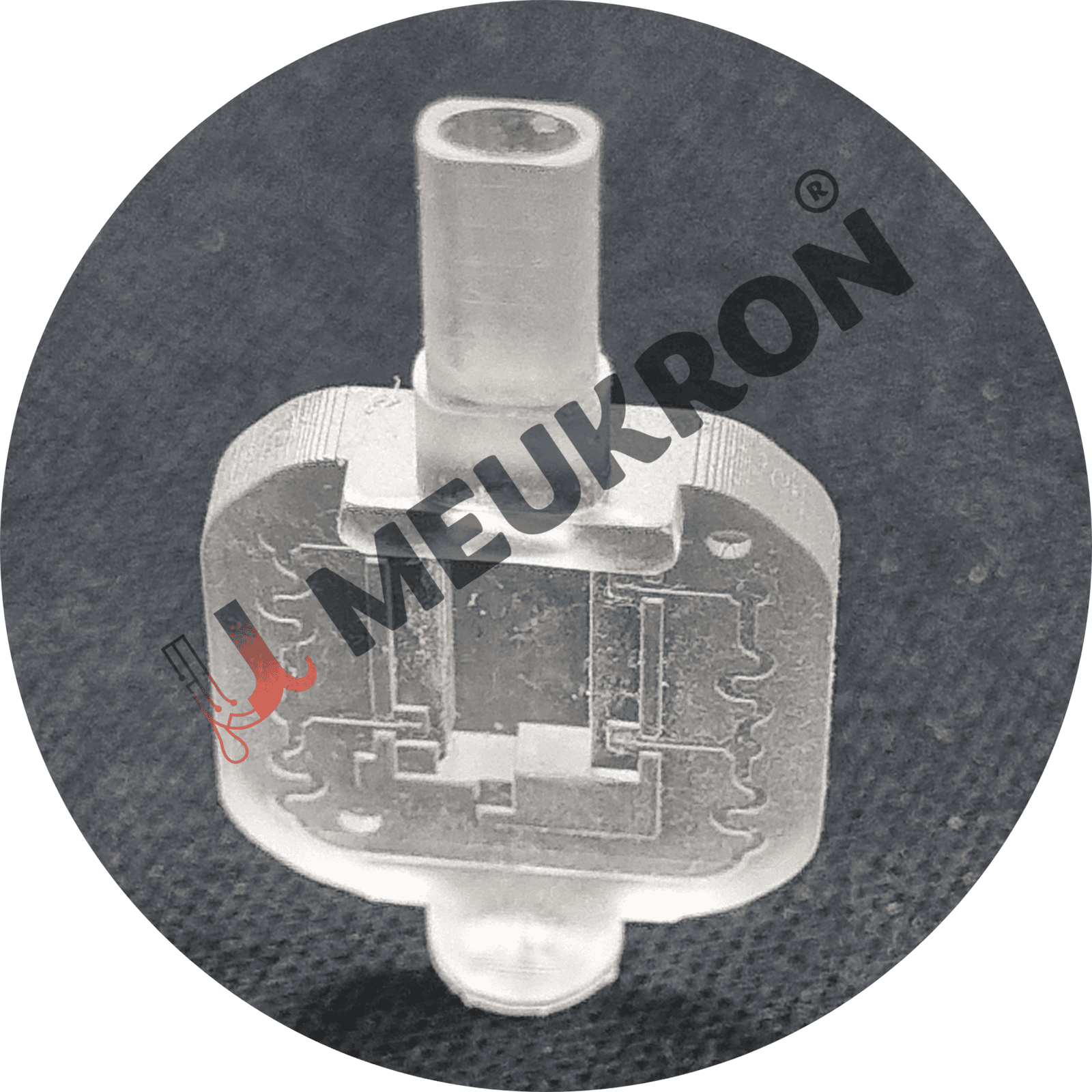

Microfluidics is the science and technology of manipulating and controlling fluids at a very small scale — typically in channels with dimensions ranging from tens to hundreds of micrometers. It involves the precise handling of tiny volumes of liquids (often nano-liters or pico-liters) using micro-fabricated devices.

Microfluidic systems integrate fluidic, mechanical, and sometimes electrical functions onto a single chip — often called a lab-on-a-chip — enabling fast, efficient, and automated chemical or biological analysis. These systems are widely used in areas like biomedical diagnostics, drug development, cell biology, and environmental monitoring.

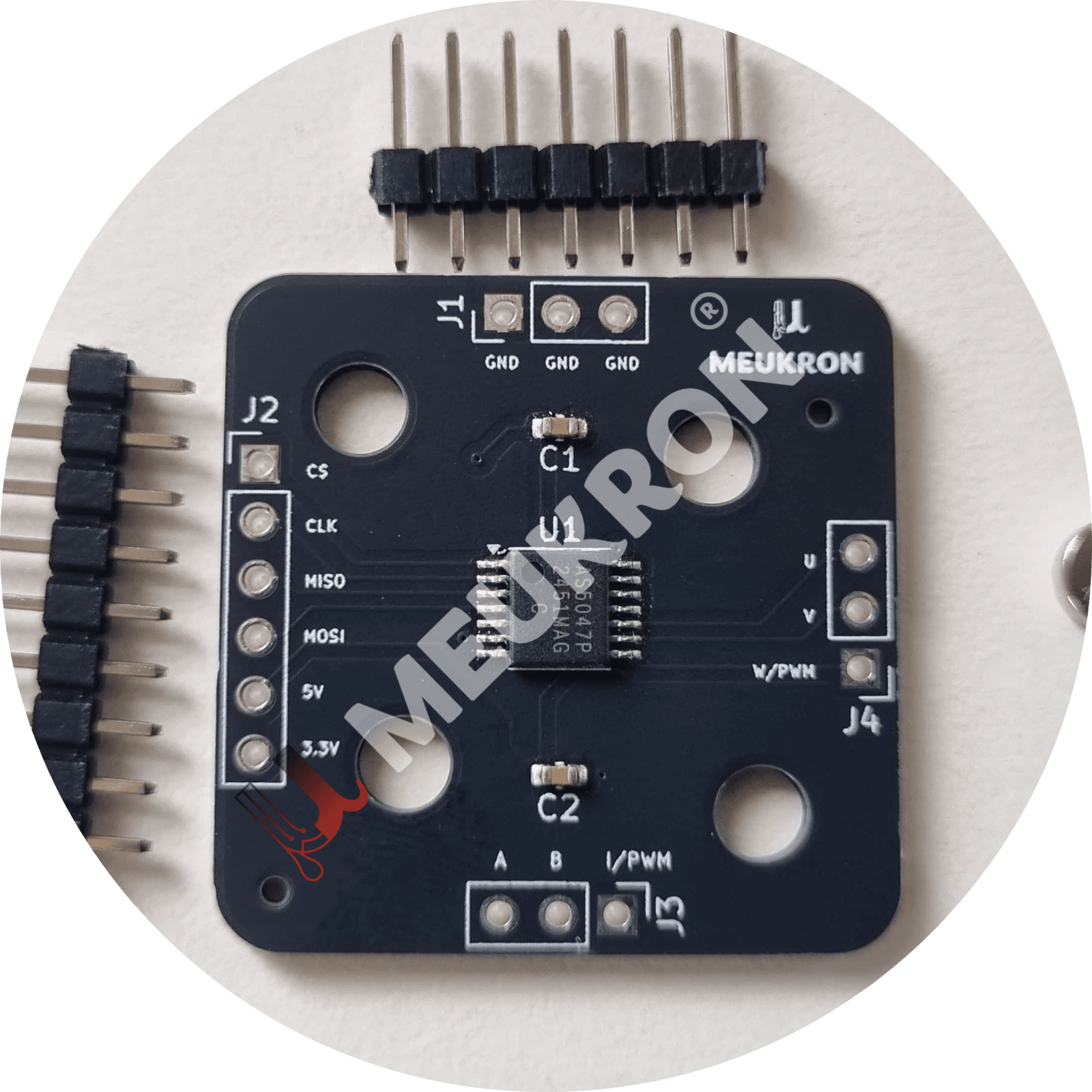

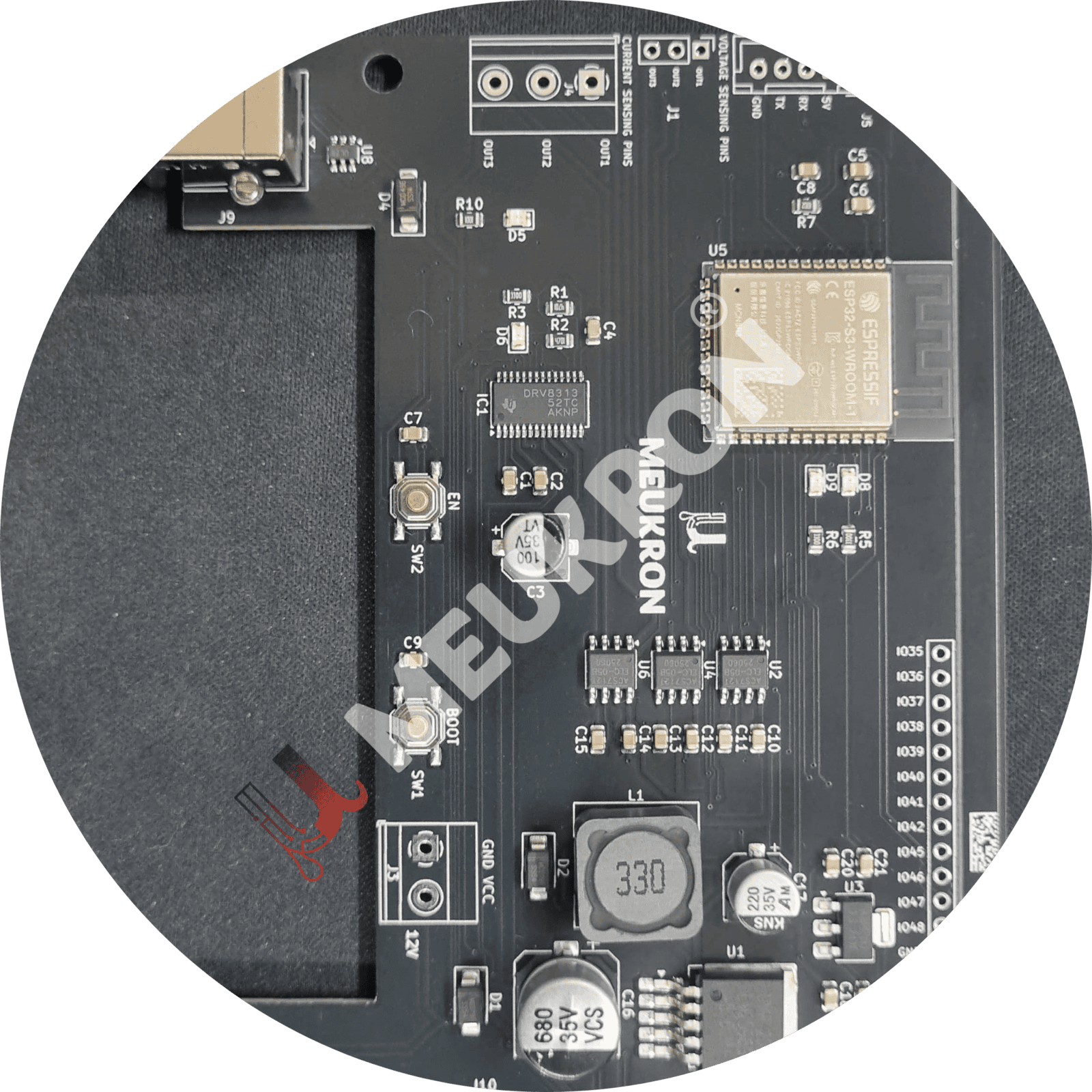

Microfluidics and electronic devices represent the convergence of fluidic control at the microscale with advanced electronics, enabling compact, intelligent, and highly functional systems. By integrating microfluidic channels with electronic circuits on a single platform, these hybrid devices can precisely manipulate fluids while simultaneously sensing, processing, and responding to data in real time.

This powerful combination forms the backbone of technologies such as lab-on-a-chip systems, wearable biosensors, point-of-care diagnostics, and automated testing platforms, where precision, miniaturization, and real-time performance are essential.

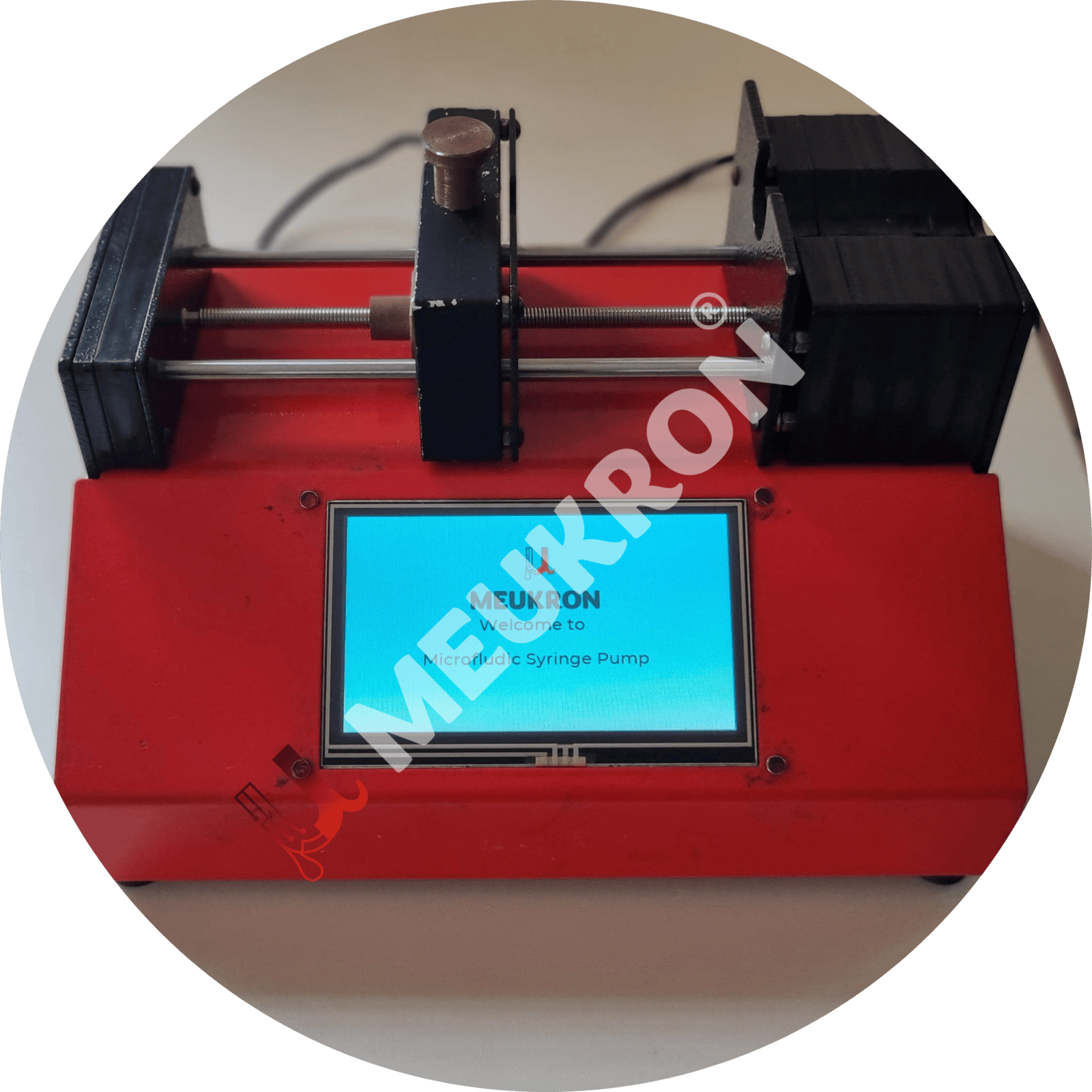

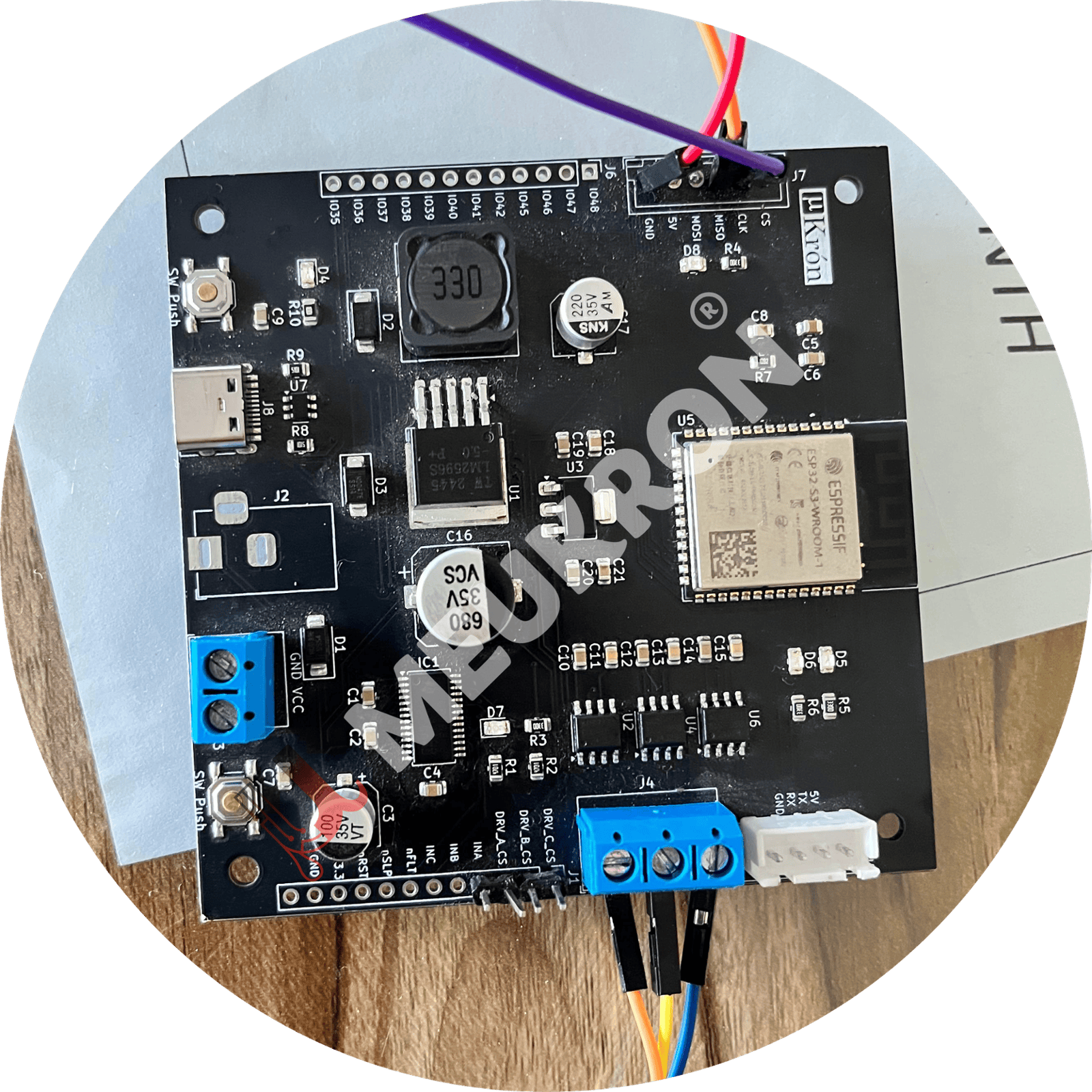

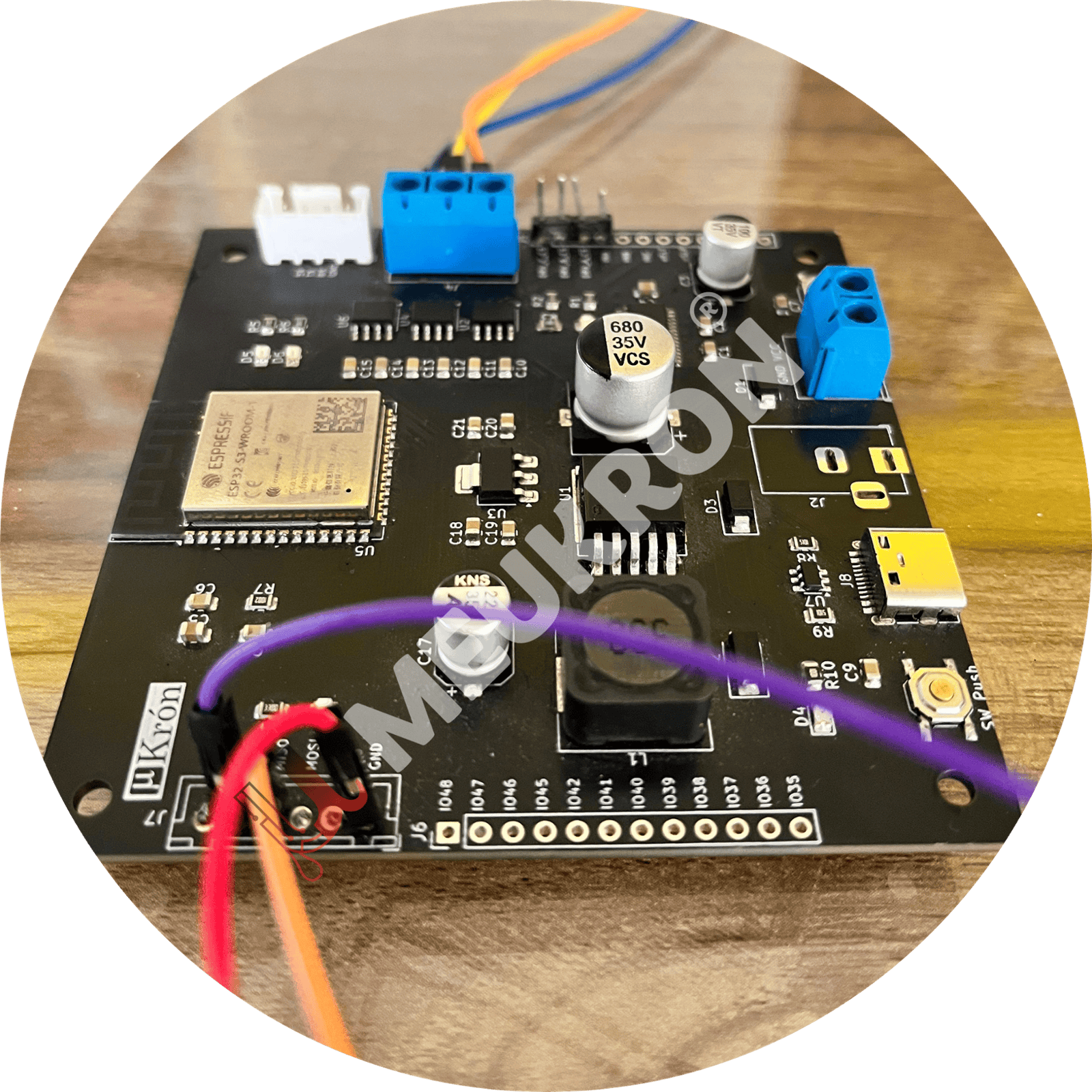

Meukron has in-house design capabilities to integrate PCB design, electronic components, and microfluidic devices, enabling seamless, application-specific solutions across healthcare, biotechnology, environmental sensing, and connected diagnostics. We use KiCad for custom PCB design and Fusion 360 for developing mechanical enclosures, ensuring fully integrated electronic–mechanical systems from concept to prototype.

A few of the in-house products developed as accessories for microfluidic applications include ultra-low flow rate syringe pumps capable of delivering as low as 1 micro-liter per second, along with custom pumping solutions tailored to specific customer requirements.